Article

Get to know the STILRIDE 1

Albeit unconsciously, the first notion of the STILRIDE 1 was first conceived in 1993 when Tue Beijer sat in his childhood room with a mind full of ideas and scrunched up sketching papers. He had envisioned the ultimate motorcycle silhouette, preferably capable of holding an electric motor, since he was a child — and suddenly something just clicked when he looked down at his desk.

— Two years later I had designed my first concept bike, inspired from that first design line I drew. We call it the “grandfather”! And over the years that silhouette has been an inspiration to see whether it’s possible to manufacture and replicate it, Tue says.

Some 30 years later the STILRIDE 1’s bespoke and future-forward design still resembles its ancestor. And like originally envisioned, STILRIDE 1 is fully electric. Short and comfortable trips on elegant motorbikes are certainly not dependent on a combustion engine, quite the opposite. An electric motor elevates the experience of luxury and comfort, offering a smooth, quiet, and sustainable ride.

Tue with his first concept bike back in 1995

— For many electrical bikes today, it almost feels like starting a computer game, with sounds, lights, and screens to make up for the starting sounds from a combustion engine. We have created something completely opposite, with a straightforward and tactile experience. Our drivers should feel like they’re in control, and the bike is designed to be the ultimate tool for driving.

Yet, STILRIDE 1 is a highly technological bike equipped with smart connectivity and advanced safety measures. The Electric Vehicle Control Unit (eVCU) offers advanced connectivity features and interfaces through an official app, with updates on battery life and performance optimization. The connected GPS positioning means services like map positioning and anti-theft alert help owners stay safe. Speaking of safety, the meticulously designed brake system in STILRIDE 1 is co-developed with pioneering motorcycle brake manufacturer ISR and global tire manufacturer Continental.

To get ergonomics and comfort to a tee,STILRIDE has tried out dozens of body types to make sure that the suspension, saddle, and handlebar are attuned. Even the president of Vespa Sweden has put in his fair share of test drive hours. Some 30 years after Tue drew up his first sketch, STILRIDE has now built a product fine-tuned to perfection.

— Over the years that first silhouette has been an inspiration to see whether it’s possible to manufacture and replicate it. 30 years later, with the help of our steel folding technique, it’s come true.

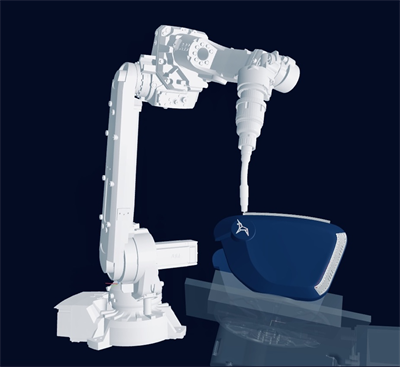

The deciding factor and the very core of STILRIDE 1’s existence is spelt STILFOLD, the technology that has given STILRIDE a unique passage to sustainable bike-part production with minimal waste and cost. Similar to how tailors pattern and cut flat pieces of garments, our STILFOLD technology realizes the full potential of flat sheet metal.

This is not only vital in the production phase of the STILRIDE 1’s appearance, it also goes hand in hand with STILRIDE’s no-nonsense stance on sustainability.

— The production line is inside our Stockholm HQ, where the human touch of our design team is translated into advanced robotics. It’s our ambition to use as climate-neutral materials as possible, which naturally means relying on local resources. Swedish stainless steel is not only internationally renowned for its quality but is also very clean, Tue concludes.